our services

on-site repair

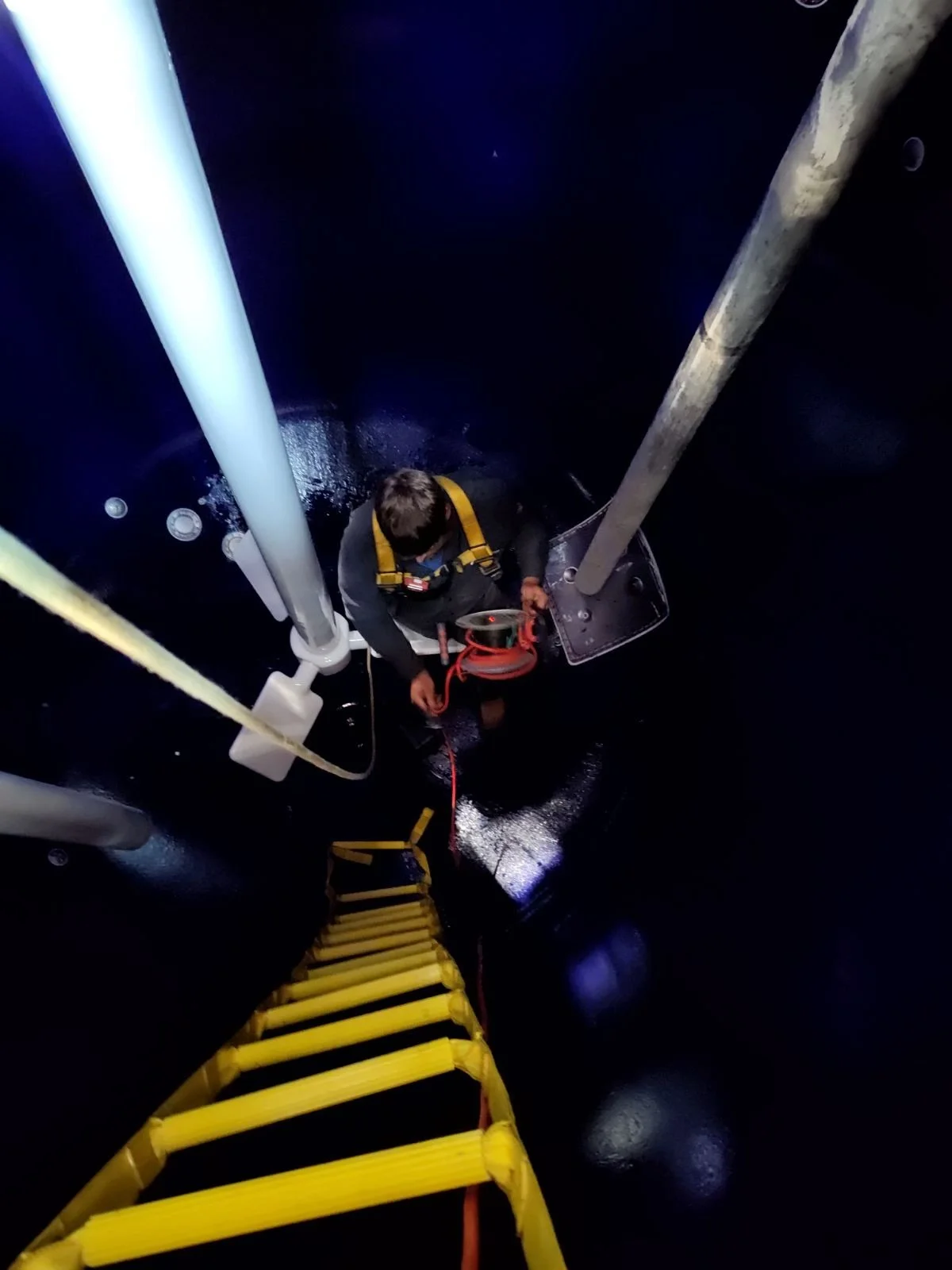

Service technicians are “PICS pre-certified” to work in hundreds of plants worldwide; they are certified for Confined Space Entry and can be available around the world, around the clock.

Glasslined Technologies operates with the latest, most technologically advanced tools and can supply its own PPE as a job site requires. Our team can also assist with Planned Maintenance shutdowns.

Glass Integrity

Visual inspection

Statistical glass thickness mapping

Spark testing

Repairs

Sleeve installation: Tantalum/ PTFE

Tantalum patches & plugs installation

Agitation systems (1 & 2 pieces) mounting/ dismounting

Mechanical seal replacement

Drive system repair or replacement

System Integrity

Failure analysis

System consultation

System installation consultation

System removal consultation

Used equipment inspection, on or off site

Inspection of third party repairs

Training Seminars

On-site

Tailored to suit the customer’s needs

Rigging

System or vessel installation/ removal

System or vessel assembly/ disassembly

Construction site consultation

Agitation system (1 & 2 piece) installation/ removal

Accessory installation/ removal

Drive Integrity

Drive inspection, evaluation and diagnosis

Mechanical seal evaluation

Vessel Inspection

Glasslined pressure vessels should be periodically inspected with frequency based on process chemistries.

At Glassedlined Technologies, we perform the highest quality inspections with documented evidence of the performance and condition of the vessel. Detailed inspections provide data necessary to predict failures and aid preventative maintenance.

Our Inspections include:

Glass thickness measurements using statistical mapping

Spark testing

Photographic depiction of issues

Condition verification of motors, seal housings, shafts

Certification document

We will archive your results for future reference

plant assembly & Disassembly

Our trained staff are available to dismantle or demolish end-of-life structures and facilities. We operate with a “safety first” ethos while offering our customers the maximum return on their investment.

More importantly, count on GTI to aid you in asset recovery.

Recovered equipment is subject to a full range of dispositions from the resale, refurbishment, and purchase for inventory, or scrap. Our customers are secure in the knowledge that GTI is fully insured, well-trained, and always focused on safety.

Glass Integrity

Visual inspection

Statistical glass thickness mapping

Spark testing

Drive Integrity

Drive inspection, evaluation, and diagnosis

Mechanical seal evaluation

System Integrity

Failure analysis

System consultation

System installation consultation

System removal consultation

Used equipment inspection, on or off-site

Inspection of third-party repairs

Training Seminars

On-site

Tailored to suit the customer’s needs

Rigging

System or vessel installation/ removal

System or vessel assembly/ disassembly

Construction site consultation

Agitation system (1 & 2 pieces) installation/ removal

Accessory installation/ removal

Repairs

Sleeve installation: Tantalum/ PTFE

Tantalum patches & plugs installation

Agitation systems (1 & 2 pieces) mounting/ dismounting

Mechanical seal replacement

Drive system repair or replacement

consulting

Our team provides consulting services for clients in North America's chemical, plastics, flavor, pharmaceutical, and petrochemical industries.

Contracted Maintenance

Reactor Care Plus+ Program is a flexible and configurable support package designed to fit the needs of any glasslined reactor/vessel user. We know that every facility is different, and support requirements differ as well. With our Reactor Care Plus+ Program Service offerings, you can specify the level of coverage needed to keep your facility and its manufacturing systems running smoothly and cost-effectively. We can tailor make a plan to satisfy your needs.

A tailored service plan allows you to supplement your own support staff in whatever way meets your requirements. Glasslined Technologies field engineers have the most comprehensive training and experience in the industry. We have more total experience than any other USA-owned, and based glasslined equipment supplier. They are equipped to access key support data and technical expertise 24/7, and they are empowered to respond to your needs quickly and cost-effectively.

Buy Back Program

Got Surplus Equipment? We've Got Solutions!

Our dedicated team is eager to repurchase and recycle your extra parts and reactors, giving those materials a brand-new lease on life.

We offer credit or purchase options for a variety of used glass-lined equipment, including:

Reactors

Agitators

Agitator shafts/hubs

Access covers

Flush valves

Let’s work together to turn your surplus into valuable resources! Contact us today to learn more about how we can assist you.