REACTORs & vessels

REACTORs & vessels

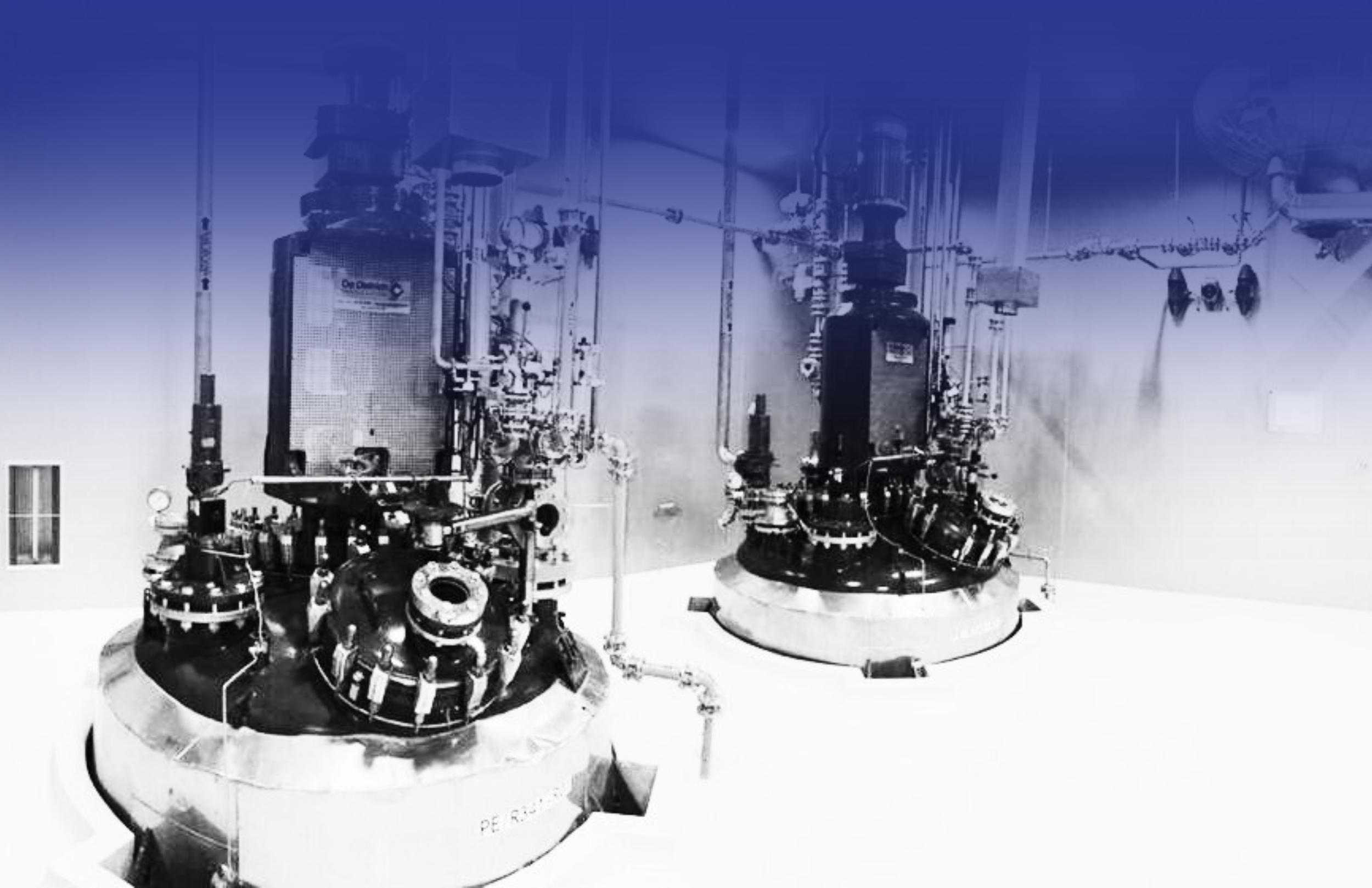

restored reactors

Refurbished Glasslined Reactors

We sell bare reactor bodies or vessels with any combination of accessories. In addition to complete reactors, we provide or repair agitators, baffles, covers, gaskets, drives, seals, and everything you need to put them into production right away.

When glass is fused to a carbon steel substrate, you get a highly corrosive-resistant vessel that is inert to almost any substance. It is smooth, easy to clean, and does not affect the flavor, color, or purity of products. Glass-lined Steel is strong, capable of handling high temperatures, requires little maintenance, and generally has a long life. It is one of the most economical and corrosive-resistant products on the market today.

All vessels are shipped with detailed inspection reports that include spark test, glass thickness mapping, and U1 compliance.

Horizontal or vertical storage tanks are a cost-effective solution for various storage requirements. Glasslined tanks are ideal for the storage and containment of corrosive chemicals or high-purity pharmaceuticals.

Either vertical (VT) or horizontal (HT) tanks are available and range from small 15-gallon up to very large 35,000-gallon capacity. Pressure and temperature specifications are needed to supply the perfect solution. All storage tanks are reconditioned and covered by a one-year warranty.

storage tanks

Re-glassing reactors

Re-glassing of worn or damaged reactors is a cost effective and quick way to get your plant back running at full capacity. GTI can re-glass vessels up to 5,000 gallons. If you are in need of something larger we can work with you to find the best solution.

GTI’s glass is warrantied for re-glass failure for 12 months.

Why Re-Glass at GTI?

We encourage the owners of glass-lined steel equipment to re-glass their worn or damaged equipment in order to achieve the maximum value from their initial investment in their core stock and to reduce the time required to acquire replacement equipment.

Ceramic Coating Company (CCC) was a manufacturer of Glasslined Reactors located in Newport, Kentucky, from the mid-1970s through the early 2000s. CCC manufactured glass-lined reactors up to 4,000 gallons, storage tanks up to 10,000 gallons, as well as reactor accessories.

CCC had a particular focus on Pfaudler-compatible products with their full line of identical reactors, drives, and parts. CCC offered replacement parts such as manway covers and drive systems compatible with Pfaudler DTW and RW drives.

We at Glasslined Technologies are in possession of Ceramic Coating Company records, including part designs and customer records for the 1980s and 1990s. We frequently receive inquiries regarding as-built designs and records of purchases for existing CCC systems; if your facility employs CCC equipment, contact GTI for additional information.